iHeir-666水性三防整理剂

防水、防油、防沾污,荷叶状疏水效果。

Waterproof, oil and dirt proof, lotus leaf hydrophobic effect.

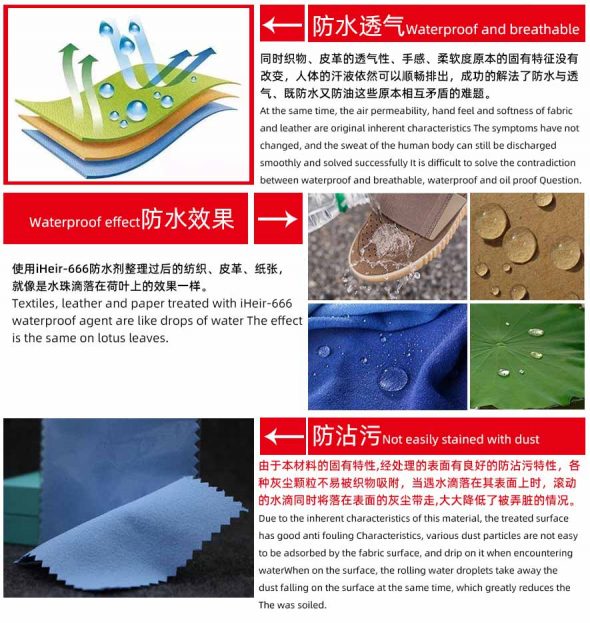

iHeir-666水性三防整理剂是氟系三防整理剂通用型,不含APEO(烷基苯酚聚氧乙烯醚),不含PFOS,PFOA含量在1ppm以下。iHeir-666水性三防整理剂可用于纺织、皮革材料、纸浆的防水、防油、防沾污处理,可以使织物拥有防虹吸、防水的效果,并且不会改变材料本身特性及透气性。纺织物经iHeir-666水性三防整理剂处理后,防水剂成分可与纤维中牢固结合,它改变了纤维表面疏水性能,使纤维表面由亲水性变为疏水性,不渗水,不吸水、不润湿而是形成水珠流走,可耐水洗50次。

iHeir-666 aqueous three proofing finishing agent is a general type of fluorine three proofing finishing agent, Excluding APEO (alkylphenol polyoxyethylene ether), no PFOS, PFOA content below 1ppm. iHeir-666 water-based three anti finishing agent can be used for waterproof, oil-proof and stain proof treatment of textile, leather materials and pulp, which can make the fabric anti siphon and waterproof, and will not change the characteristics and air permeability of the material itself. After being treated with iHeir-666 water-based three anti finishing agent, the textile will be anti siphon The water agent component can be firmly combined with the fiber. It changes the hydrophobic performance of the fiber surface from hydrophilicity to hydrophobicity. It does not penetrate water, absorb water or wet, but forms water droplets to flow away, and can withstand water washing for 50 times.

理化指标

Physical and chemical indicators

|

化学组成 Chemical composition |

全氟聚合物乳液 Perfluoropolymer emulsion |

|

外观 Appearance |

浅土黄色乳状液,澄清、半透明状 Light earthy yellow emulsion, clear and translucent |

|

离子性 Ionicity |

弱阳离子 Weak cation |

|

pH值 pH value |

3~4(pH广范试纸) 3~4 (pH wide range test paper) |

|

固含量 Solid content |

19~21%(烘干法:2g乳液,130℃×3hrs) 19~21% (drying method: 2g emulsion, 130℃×3hrs) |

|

溶解性 Solubility |

在冷水中溶解,常温下迅速溶解于水 It dissolves in cold water and rapidly dissolves in water at room temperature |

产品特性

Product features

-

不含APEO(烷基苯酚聚氧乙烯醚),不含PFOS,PFOA含量在1ppm以下。

Do not contain APEO (alkylphenol polyoxyethylene ether), PFOS and the PFOA content below 1ppm. -

处理涤纶、尼龙等化纤织物的用量非常低。

The amount of polyester, nylon and other chemical fiber fabrics is very low. -

产品为不可燃的水基乳液。

The product is a kind of water based emulsion that is non flammable. -

推荐用于涤纶、尼龙、涤棉混纺等织物的三防整理。

It is recommended to be used in three proofing finishing of polyester, nylon and polyester cotton blended fabrics. -

生产适用性广:iHeir-666的拒水、拒油性能对工作液pH值不敏感。

Wide applicability: the water and oil repellency of iheir-666 is not sensitive to the pH value of working solution. -

织物在保持其天然手感、外观和透气性的同时被赋予了防护功能。

The fabric is endowed with protective function while maintaining its natural handle, appearance and air permeability. -

可通过喷淋、发泡、刮涂、湿润辊、浸轧、吸尽法等方式进行应用。

It can be applied by spraying, foaming, scraping, wetting roller, dip rolling, suction method and so on. -

与其它纺织助剂并用时,具有优良的稳定性。

It has good stability when used with other textile auxiliaries.

应用技术资料

Applied technical data

1、织物的准备

◆ 为获得最佳效果,必须除去预整理织物上所有的残留助剂,如:润湿剂、染色助剂、浆料残留物、柔软剂及其它表面活性剂。

◆ 织物掉纤率必须小于等于1.5%,建议通过AATCC97进行测试。另外,必须保证布料呈弱酸性,含碱率小于等于0.05%,建议通过AATCC 144进行测试。

◆ 为避免降低效果,起绒和砂磨加工应在整理前进行;一些机械整理,如:轧光、电光、刷毛等可在烘干后培烘前进行;汽蒸和蒸化加工在焙烘后进行可提高整理效果。

1. Fabric preparation

◆ In order to obtain the best effect, all the residual auxiliaries, such as wetting agent, dyeing aid, size residue, softener and other surfactants, must be removed from the finished fabric.

◆ The fiber drop rate of fabric must be less than or equal to 1.5%. It is recommended to pass the AATCC97 test. In addition, it is necessary to ensure that the fabric is weakly acidic, and the alkali content is less than or equal to 0.05%. It is recommended to pass the AATCC 144 test.

◆ In order to avoid reducing the effect, pilling and sanding should be carried out before finishing; Some mechanical finishing, such as calendering, electro-optic, brushing, can be carried out after drying and before baking; Steaming and steaming after baking can improve the finishing effect.

2. Preparation of working fluid

◆ First, add the required amount of iHeir-666 water repellent in the clean bucket, then add the tap water slowly. After that, stir for 5~10min at low speed until the solution is mixed evenly, so that a large amount of foam will be avoided.

◆ When bathing with cross-linking agent, penetrant, wrinkle resistant resin and other additives, please test the compatibility and stability of these additives with iHeir-666 in advance. It is supposed to dilute these products and waterproof agents separately to avoid mixing with the original solution.

2、工作液的调配

◆ 先在干净料桶中预先加入所需量的iHeir-666防水剂,再缓慢加入所需量的自来水,添加完自来水后,最后再低速搅拌5~10min至溶液混合均匀即可,避免产生大量泡沫。

◆ 与交联剂、渗透剂、防皱树脂及其它助剂同浴时,请预先测试这些助剂与iHeir-666的相容稳定性,并要求首先将这些产品和防水剂都分别稀释,避免原液相混合。

3、用量推荐

使用浓度因加工织物的种类、组织结构、清洁度、酸碱度、掉纤率以及客户所需达到的防护效果及耐洗要求而变化,一般用量如下:

◆ 涤纶织物 8~20g/l

◆ 尼龙织物 5~20g/l

◆ 涤/棉织物 20~50g/l

◆ 纯棉织物 30~50g/l

3. Recommended dosage

The use concentration varies with the type of fabric, fabric structure, cleanliness, pH, fiber drop rate, and the protection effect and washability required by customers

◆Polyester fabric 8~20g/l

◆nylon fabric 5~20g/l

◆Polyester / cotton fabric 20~50g/l

◆Pure cotton fabric 30~50g/l

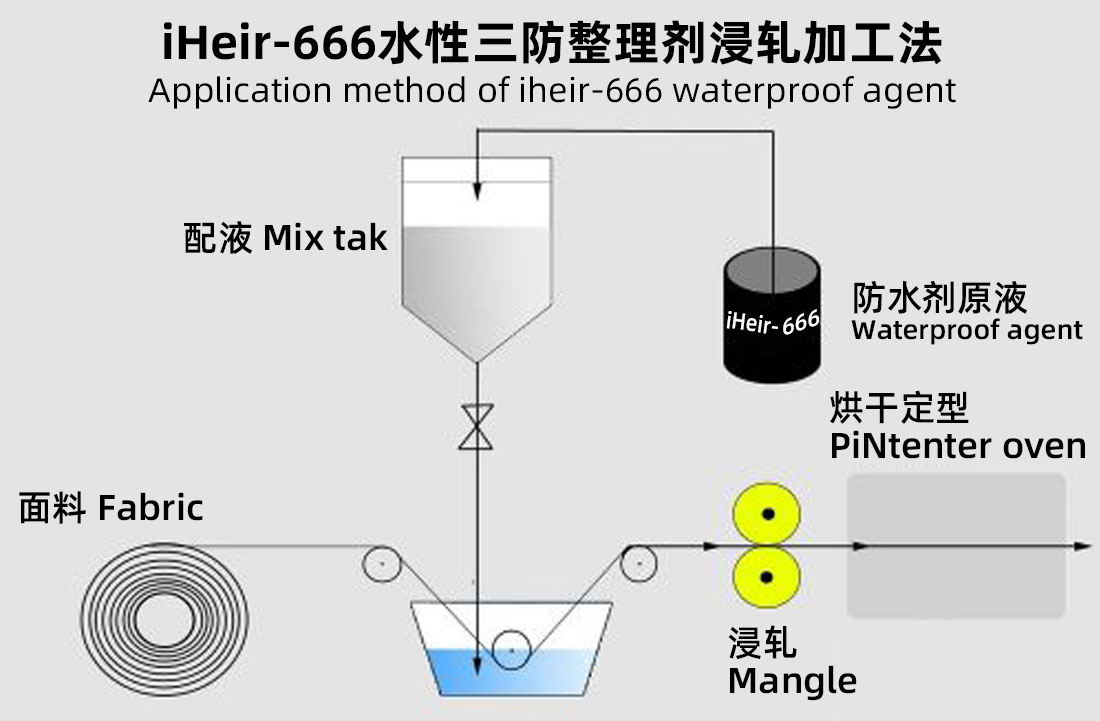

4. Application method

◆ Dip rolling method One immersion and one rolling(“Three dipping and one rolling” recommended in laboratory test)

◆ Pre drying 110~130℃

◆ Baking (shaping) It is recommended to bake 60Sec in 170 ℃ (cloth surface temperature) section of stenter

4、应用方法

◆ 浸轧方法 一浸一轧(实验室小试推荐“三浸一轧”)

◆ 预烘干 110~130℃

◆ 焙烘(定型) 推荐在拉幅定型机170℃(布面温度)段焙烘60Sec

5、使用注意事项

◆与其它助剂拼用前,必须通过预备实验,充分确认与拼用药剂的相容性。

◆调配处理液时要缓慢搅拌,避免产生大量泡沫。

◆含氟防水剂有深色效果,请预先确认加工后的色调变化。

◆焙烘一定要充分,否则不能发挥最优秀的防护性能,建议根据机台条件预先实验。

◆请尽量在12小时内将配制的处理液用完;长时间放置的处理液,确认后方可使用。

◆由于树脂渣易黏附、堆积在辊筒上,因此辊筒干燥不是理想的方法。

5. Precautions for use

◆ Before mixing with other additives, the compatibility with the mixing agent must be fully confirmed through preliminary experiments.

◆When mixing the treatment fluid, it should be stirred slowly to avoid foaming.

◆ Fluorine containing waterproof agent has dark color effect, please confirm the color change after processing in advance.

◆ Baking must be sufficient, otherwise it can not play the best protection performance. It is suggested to test in advance according to the machine conditions.

◆ Please use up the prepared solution within 12 hours as much as possible; The treatment solution stored for a long time can only be used after confirmation.

Since the resin residue is easy to adhere and accumulate on the roller, so roller drying is not an ideal method.

低用量时的加工性能

Machinability at low dosage

● 防水剂用量与初始拒水、拒油效果

●Effect of water repellent dosage on initial water and oil repellency

1、320T墨绿色春亚纺(100%涤纶)

1. 320T dark green polyester pongee (100% polyester)

|

拒水性 Water repellency |

iHeir-666用量 iHeir-666 dosage |

3 g/l |

5 g/l |

8 g/l |

10 g/l |

20 g/l |

|

工作液pH≈6 Working fluid pH≈6 (210+自来水) (210 + tap water)

|

70 |

85 |

100 |

100 |

100 |

|

|

工作液pH≈4Working fluid pH≈4 (210+自来水+1g/l醋酸) (210 + tap water + |

80 |

95 |

100 |

100 |

100 |

2、228T藏青色塔丝隆(100%尼龙)

2. 228T Navy Taslon (100% nylon)

|

拒水性 Water repellency |

iHeir-666用量 iHeir-666 dosage |

3 g/l |

5 g/l |

8 g/l |

10 g/l |

20 g/l |

|

工作液pH≈6 Working fluid pH≈6 (210+自来水) (210 + tap water)

|

70 |

100 |

100 |

100 |

100 |

|

|

工作液pH≈4Working fluid pH≈4 (210+自来水+1g/l醋酸) (210 + tap water + |

85 |

100 |

100 |

100 |

100 |

3、白色涤/棉混纺(80T/20C)

3. White polyester / cotton blend (80T/20C)

|

iHeir-666用量 iHeir-666 dosage |

10 g/l |

20 g/l |

30 g/l |

50 g/l |

100 g/l |

|

|

工作液pH≈6 Working fluid pH≈6 (210+自来水) (210 + tap water) |

拒水性 Water repellency |

85 |

85 |

100 |

100 |

100 |

|

拒油性 Oil repellency |

4 |

6 |

6.5 |

6.5 |

7 |

|

4、白色棉(100%棉)

4、White cotton (100% cotton)

|

iHeir-666用量 iHeir-666 dosage |

10 g/l |

20 g/l |

30 g/l |

50 g/l |

100 g/l |

|

|

工作液pH≈6 Working fluid pH≈6 (210+自来水) (210 + tap water) |

拒水性 Water repellency |

85 |

85 |

85 |

85 |

100 |

|

拒油性 Oil repellency |

2 |

5 |

6 |

6.5 |

6.5 |

|

5、其它实验条件

实验用水:自来水

初始工艺工作液:200ml/2pcs样布

浸轧方式:干布在料槽中连续翻3次→让工作液浸透织物→轧1次(实验室小试)

小轧车控制条件:0.4MPa,2m/min

带液率:春亚纺80%,塔丝隆67%,白色涤/棉60%,白色棉73%

定型条件:涤纶、尼龙170℃×1min

涤/棉、棉170℃×2min(烘、培一步完成,未做预烘干处理)

5. Other experimental conditions: tap water

Initial working fluid: 200ml / 2pcs sample cloth

Dip rolling method: dry cloth in the trough for three times continuously → let the working fluid soak the fabric → rolling once (laboratory small test) small rolling car control conditions: 0.4MPa, 2m / min

Liquid rate: polyester pongee 80%, Taslon 67%, white polyester / cotton 60%, white cotton 73%

Setting conditions: polyester, nylon 170 ℃ × 1min

Polyester / cotton, cotton 170 ℃ × 2min (baking finish in one step without pre drying)

6、工作液pH值调节方式

降低pH值用99%工业醋酸(pH≈3)

提高pH值用10%碳酸钠溶液(pH≈11)

工作液pH值测试方法:pH广范试纸

6. Adjustment mode of pH value of working fluid

Reduce pH value: use 99% industrial acetic acid (pH ≈ 3)

Increase pH value: use 10% sodium carbonate solution (pH ≈ 11) as working fluid

PH test method: pH wide range test paper

7. Experimental fabric

320T dark green Chunya: 100% polyester, 57 g / m2.

228T Navy Taslon: 100% nylon, 107 g / m2.

White polyester / cotton: 80T / 20c, warp “21S / 1 T / C 80 / 20 polyester / cotton blended yarn”, weft “16S / 1 T / C 80 / 20 polyester / cotton blended yarn”, warp and weft density 127 × 57 pieces / inch, 235g / m2.

White cotton: 100% cotton, left twill woven fabric, warp “21S / 1 pure cotton yarn”, weft “21S/ 1 pure cotton yarn”, warp and weft density 118 × 60 pieces / inch, gram weight 193g / m2.

7、实验织物

320T墨绿色春亚纺:100%涤纶,57 g/m2。

228T藏青色塔丝隆:100%尼龙,107 g/m2。

白色涤/棉:80T/20C,经纱“21S/1 T/C 80/20 涤/棉混纺纱”,纬纱“16S/1 T/C 80/20 涤/棉混纺纱”,经纬密127×57根/英寸,235g/m2。

白色棉:100%棉,左斜纹梭织布,经纱“21S/1纯棉纱”,纬纱“21S/1纯棉纱”,经纬密118×60根/英寸,克重193g/m2。

8、拒水性评价标准:美国AATCC 22,最好100分,最差0分。

AATCC 22, the best is 100 points and the worst is 0 points.

拒油性测试标准:美国AATCC 118,要求抗油纺织品的拒油等级至少达5级。

Oil repellency test standard: American AATCC 118, which requires that the oil repellency grade of oil resistant textiles should be at least 5.

包装规格、储存和安全注意事项

Package specification,Storage and safety considerations

试样采购可提供1KG、5KG、10KG三种分装规格。

Pilot procurement can provide 1kg and other packaging specifications.

正常量产采购只提供25KG的蓝色塑料桶包装规格。

Normal mass production procurement only provides 25kg blue plastic bucket packaging specifications.

iHeir-666在密闭容器中适当保存可稳定1年,本品高于40℃或低于0℃时敏感。

iHeir-666 can be kept in a closed container for one year. It is sensitive when the temperature is higher than 40 ℃ or lower than 0 ℃.

开启后注意密封,避免明火和在太阳下直接暴晒,置阴凉通风仓库。

After opening, pay attention to sealing, avoid open fire and direct sun exposure. It is supposed to be stored in a cool and ventilated warehouse.

本品的存放、运输和使用中应遵守化学品贮运的一般卫生安全规定,不可吞服。

The storage, transportation and use of this product should comply with the general health and safety regulations of chemical storage and transportation. The product should not be swallowed.

温馨提醒

kindly reminder

1、建议您佩戴手套、眼罩或面罩,做好手及双目防护,避免接触皮肤及眼睛。

2、这里所提供的资料是以我们的最佳经验、长期研究和大量实验为基础的,但是商品在实际使用时的环境和工艺条件非我公司所能控制,所以根据这些资料造成任何损失或损坏,本公司概不负责。实际生产中,根据您特定的生产环境或要求,请预先进行实验室小试。

1. It is recommended that you should wear gloves, eye mask or face mask, and protect your hands and eyes to avoid contact with skin and eyes.

2. The information provided here is based on our best experience, long-term research and a large number of experiments. However, the environment and technological conditions of the goods in actual use are beyond our control. Therefore, our company will not be responsible for any loss or damage caused by these information. In actual production, please conduct laboratory test in advance according to your specific production environment or requirements.